Including Safety and Innovation with Aluminum Handrails

Anodized aluminum railing is a beautiful and long-lasting solution for a wide range of projects. At AMI we see them called for in schools, sporting venues, commercial and office buildings, and even residentially. The styles of railing are as varied as the colors. Full hollow tube construction is one of the most popular commercial handrail system designs. This construction method is very strong and has a pleasing appearance. They also have a soft round look and feel with no sharp edges, so it is ideal for safety railing.

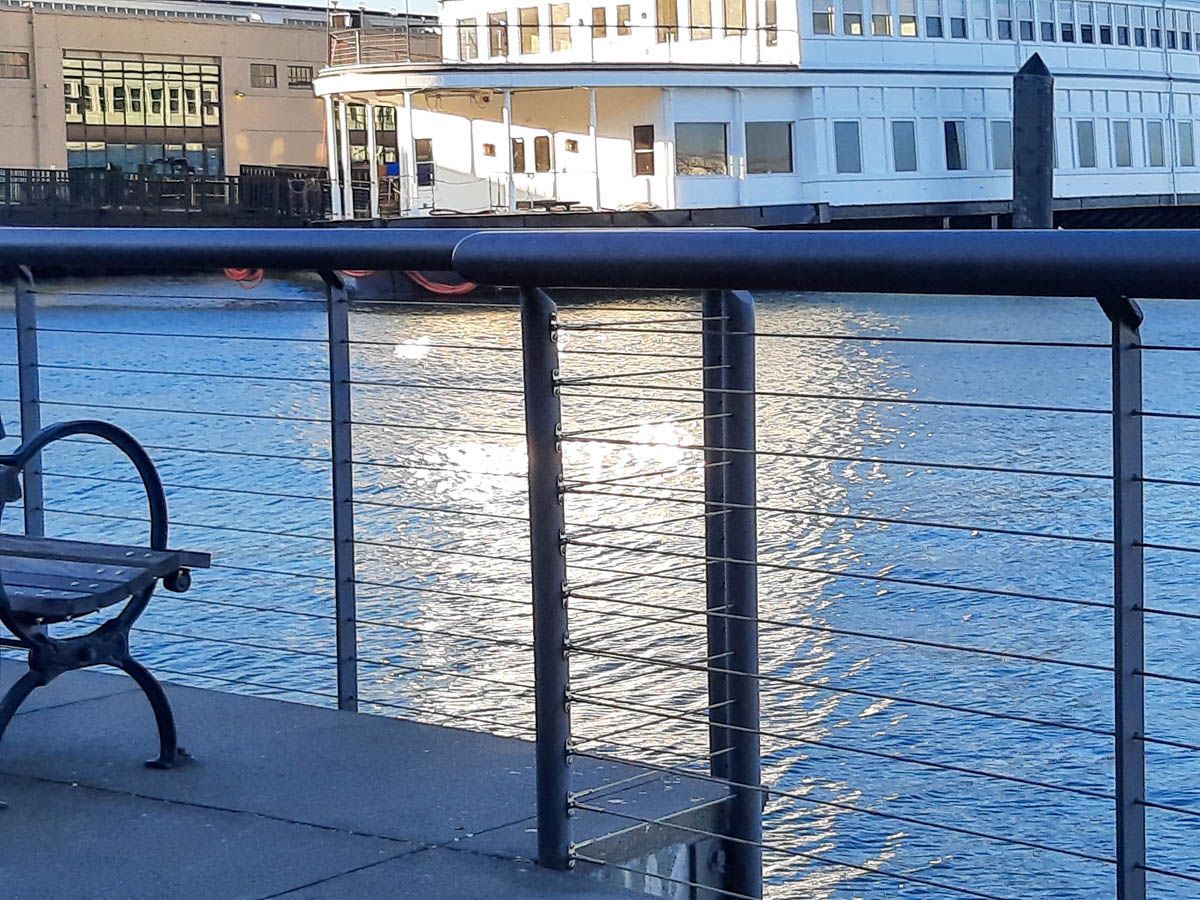

Another pleasing and more modern way anodized aluminum is used in railing systems is by mixing materials. Stainless steel cable tensioned through heave aluminum flat bar up rights creates a strong and visibly unintrusive look. If the view is the feature that needs to be show cased, but safety cannot be ignored this is an elegant solution.

Aluminum tube has also been mixed with wood and composite products residentially. This technique is a very carpenter friendly approach and requires much less planning and detailing. Just provide the lineal footage needed and normal carpentry saws can cut the aluminum to size.

When preparing for your railing job be sure to consider anodize rack attachments and drain holes. Collaborate with your AMI contact for best results.